Intelligent Multi-Agent Engineering System (iMAgES)

A digital model and software solution for optimizing oil field management scenarios.

Task

The objective is to create a tool that will enhance the efficiency of management decision-making with regard to the allocation of resources between oil fields and the determination of reference values for key performance indicators in the oil production process.

The research objective is to develop a comprehensive intelligent technical decision optimization system that draws on all available multidisciplinary information to provide an end-to-end integrated planning and control process.

A field-level integrated model is developed to optimize field management scenarios in terms of planning the drilling of new wells and implementing geological and technical measures at the base well stock.

Solution

The iMAgES system consists of three units:

- Intelligent integrated model of oil production at the Region level;

- Intelligent integrated oil production model at the Field level;

- Ontological model intended to formalize and organize heterogeneous data about the mathematical models being developed as part of the project.

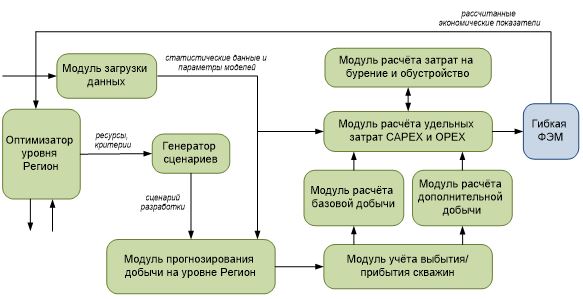

- Intelligent integrated model of oil production at the Region level

The model generates long-term solutions for a given project, represented by a Pareto front of scenarios corresponding to the given priorities of indicator provision. In order to predict oil production, the model considers the impact of changes in base production, the effect of new well commissioning, the cartographic information on reserves and free areas, and the influence of geological and technical measures (GTM) on additional production. The economic indicators are evaluated based on the oil production prediction to determine the feasibility of a given development scenario. Additionally, an optimizer has been developed as an add-on to the Region-level oil production model. This tool generates a set of scenarios, calculates them using the model, and selects the most effective ones in terms of increasing oil production or reducing costs.

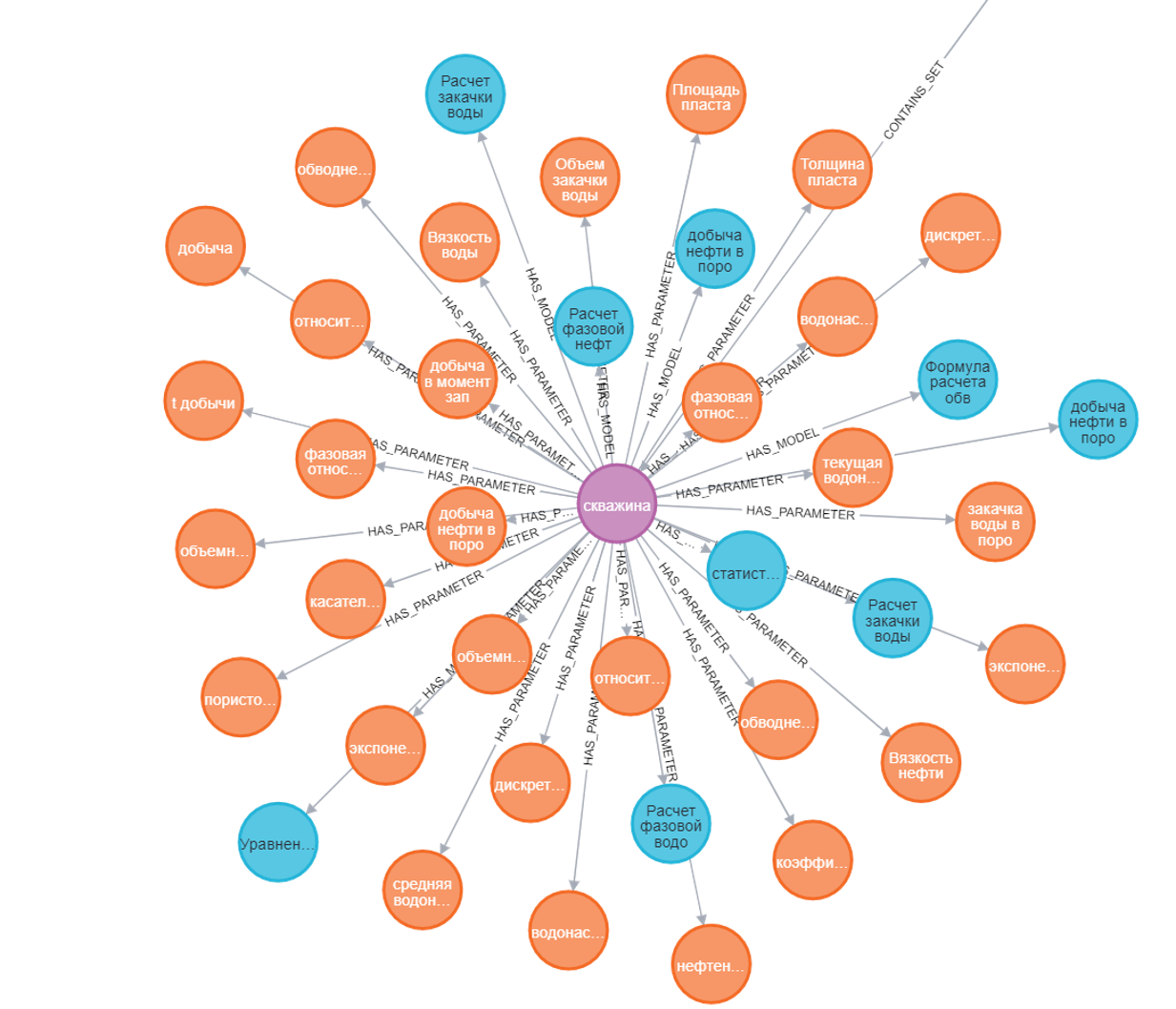

2. Integrated digital model with the requisite software of oil production at the Field level for predicting oil production from base stock wells and drilling new wells.

The model comprises two principal components:- A predictive model that forecasts the impact of a specific field development scenario in terms of both physical and financial outcomes.

- The optimization module, which selects the parameters of field development scenarios for the predictive model that correspond to optimal values of target functions.

- The model generates a set of Pareto-optimal scenarios for field exploitation, taking into account the constraints on the use of material and financial resources.

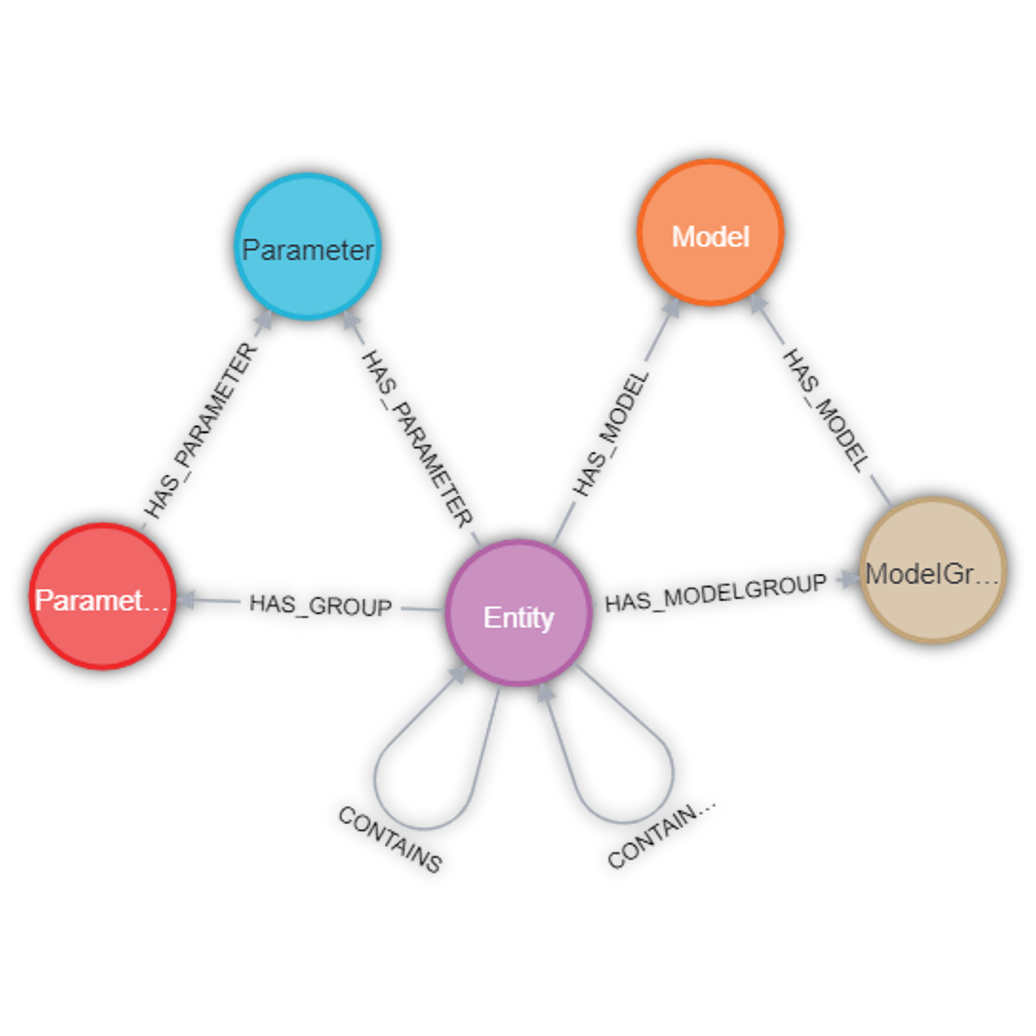

3. Ontological model for the formalization and systematization of heterogeneous data about the mathematical models under development within the project.

The structure of the ontological model for drilling and construction provides:

- The relationship between design decisions and indicators of geological and technical measures (GTM);

- The description of the types and structure of unit cost indicators for different GTM types;

- The description of standard scenarios for the development of the region and the field;

- The description of calculation schemes employed in the construction of Region and Field oil production models;

- Storage of information on potential risks.

Integrated Field Level Model

Technologies

| OS | Windows |

| Graph databases | Dgraph, Neo4j |

| Ontology representation formats | Owl, RDF |

| Programming languages | JavaScript, Python 3.10 |

| Frameworks | Node.js, pandas, FastAPI, scipy, scikit-learn |

Project team

- Project manager: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory at SPbPU

- Region level model development team lead: S.V. Lupulyak, Associate Professor, Head of the Virtual Simulation Modeling Laboratory of the Institute of Physics and Mechanics, SPbPU

- Field level model development team lead: A.M. Gintciak, Head of the Digital Modeling of Industrial Systems Laboratory, SPbPU

- Оntological model development team lead: M.B. Uspensky, Senior Researcher at the Industrial Systems for Streaming Data Processing Laboratory, SPbPU

Contributors

- Virtual Simulation Modeling Laboratory, Institute of Physics and Mechanics, SPbPU

- Digital Modeling of Industrial Systems Laboratory, SPbPU

- Industrial Systems for Streaming Data Processing Laboratory, Advanced Engineering School, SPbPU

Key contributors

- Project manager: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory at SPbPU

- Region level model development team lead: S.V. Lupulyak, Associate Professor, Head of the Virtual Simulation Modeling Laboratory of the Institute of Physics and Mechanics, SPbPU

- Field level model development team lead: A.M. Gintciak, Head of the Digital Modeling of Industrial Systems Laboratory, SPbPU

- Оntological model development team lead: M.B. Uspensky, Senior Researcher at the Industrial Systems for Streaming Data Processing Laboratory, SPbPU